Folding Mobile Container Tiny House

Product Specifications

Dimensions: Typically, the dimensions of a folding container house are 2500mm * 5800mm * 2490mm, with custom sizes available upon request.

Frame: Made from galvanized steel materials with a galvanized square tube structure to ensure the strength and durability of the house.

Walls: Usually made of 50mm rock wool board, which provides good insulation and soundproofing effects.

Roof: 0.4mm color steel plate single-layer tile, durable and easy to maintain.

Floor: Cement fiber board or glass magnesium board, providing a solid ground support.

Doors and Windows: Plastic steel security windows and high-grade steel doors to ensure safety and durability.

Electrical System: Including distribution boxes, leakage protection, five-hole sockets, switches, three-hole sockets, purification lights, etc.

Fire Resistance: Class A fire resistance.

Seismic Resistance: Capable of withstanding earthquakes up to magnitude 10.

Wind Resistance: Capable of withstanding winds up to force 10.

Service Life: Designed for a service life of 15 years.

Raw Materials

The main materials used in the construction of folding container houses include galvanized steel, rock wool board, color steel plates, cement fiber board, or glass magnesium board, all of which are characterized by high strength, durability, and environmental friendliness.

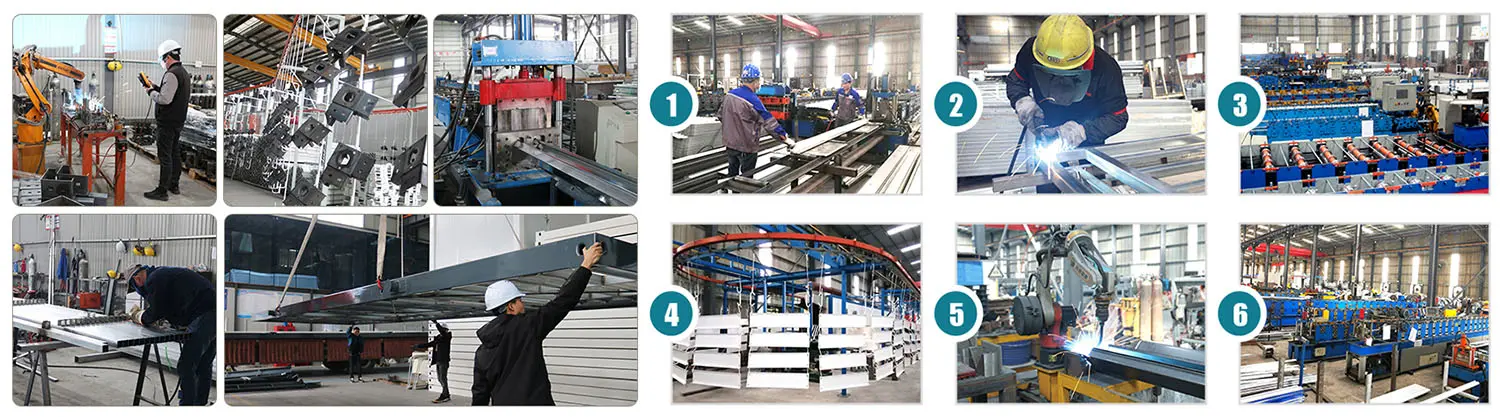

Production Process

The production process includes material cutting, welding, assembly of the frame, installation of walls and roofs, installation of doors and windows, and electrical systems. The entire process is completed within the factory to ensure quality control and production efficiency.

Usage Scenarios

Folding container houses are suitable for a variety of scenarios, including but not limited to:

Temporary Housing: Such as disaster relief, temporary housing for construction sites, etc.

Commercial Spaces: Such as retail shops, offices, etc.

Public Facilities: Such as schools, medical stations, etc.

Industrial Uses: Such as warehouses, workshops, etc.

Quality Inspection

Quality inspection includes the inspection of raw materials, quality control during the production process, and testing of the finished product to ensure that the house meets the requirements of Class A fire resistance, seismic resistance up to magnitude 10, and wind resistance up to force 10.

Packaging and Transportation

Folding container houses are properly packaged to protect the product from damage before transportation. Due to its folding design, the transportation cost is relatively low, and it is easy to transport via various modes of transport.

After-Sales Service

Comprehensive after-sales service is provided, including installation guidance, repair services, and customer consultation. Some manufacturers also offer a warranty service for a certain period, such as a three-year or 100,000-kilometer warranty service.

Payment Settlement

Payment settlement is usually made after the contract is signed and the goods are accepted as qualified. The buyer needs to provide a formal value-added tax (VAT) invoice, and then pay the full payment at once.

Please use this information to compile your product detail page. If you need more detailed data or have other specific requirements, please let me know.