Custom Exterior Flat Pack Container House: A Personalized and Modular Living Space

Product Parameters

The custom exterior flat pack container house is available in a variety of sizes, typically ranging from 6 to 12 meters in length, 3 to 6 meters in width, and 2.5 to 3 meters in height. These dimensions can be adjusted based on client needs. The unit can be designed with one to three bedrooms, along with spaces for living, dining, and kitchen areas. The exterior can be customized with various materials, textures, and colors to match the client's preferences, offering an extensive range of design possibilities from sleek modern styles to rustic or traditional looks.

Raw Materials

The primary structure of the flat pack container house is made from hot-dip galvanized steel for enhanced durability and corrosion resistance. The walls are typically composed of insulated sandwich panels, filled with polyurethane or rock wool, to provide superior thermal and sound insulation. For the exterior, customers can choose from a wide range of materials, including:

Wood Paneling: Natural wood finishes for a warm, rustic appearance.

Wood Paneling: Natural wood finishes for a warm, rustic appearance.

Stone Veneer: Decorative stone facades for a traditional, luxurious feel.

Brick Finishes: Modern brick exteriors for a timeless aesthetic.

Composite Materials: Durable and lightweight materials that mimic the appearance of wood or stone but require less maintenance. The flooring inside the house is typically reinforced plywood or cement board, designed to withstand wear and tear over time.

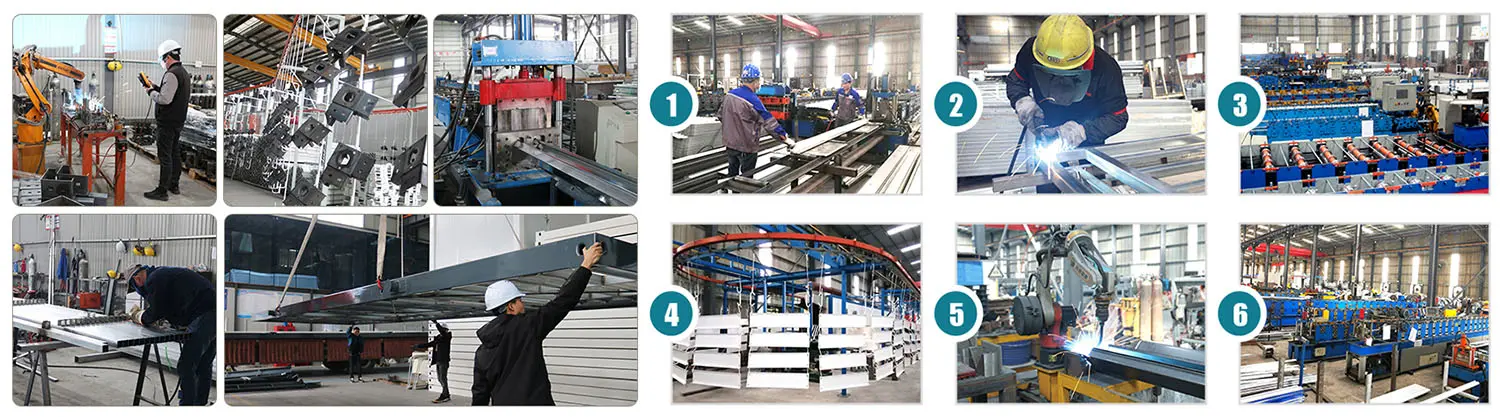

Production Process

The production process for the custom exterior flat pack container house involves the following steps:Steel Frame Fabrication: The steel frame is manufactured to provide a sturdy and durable foundation for the house.Panel Installation: Insulated sandwich panels are installed for the walls and roof, ensuring energy efficiency and weather resistance.Exterior Customization: The chosen exterior materials, such as wood, metal, or stone, are applied according to the client’s specifications. This step ensures the house matches the desired aesthetic.Interior Finishing: The interior layout is customized with partition walls, flooring, and ceiling finishes, allowing for fully tailored living spaces.Utility Pre-Installation: Plumbing, electrical wiring, and HVAC systems are installed during production for easy connection on-site.Quality Control: The house undergoes a series of quality checks to ensure it meets all structural and safety requirements before it is packaged for transportation.

Application Scenarios

The custom exterior flat pack container house is versatile and can be adapted to a variety of uses, including:Residential Homes: Perfect for homeowners looking for a personalized, low-maintenance home that reflects their unique style and preferences.Vacation Homes: Ideal as a custom-designed holiday home in picturesque locations, with the flexibility to blend into the natural environment or stand out with a modern design.Guesthouses or Rental Properties: Suitable for use as guest accommodations or rental units, offering a distinctive aesthetic that can appeal to renters or visitors.Home Offices or Studios: With customized exteriors, these container homes can serve as functional, inspiring spaces for work, art studios, or creative projects.Commercial Spaces: The customizable exterior makes this option ideal for businesses looking to create unique retail stores, cafés, or pop-up shops.

Quality Inspection

Each custom exterior flat pack container house is subject to a thorough quality inspection process, including:

Structural Integrity Testing: Ensuring the steel frame and supporting structure are capable of withstanding environmental stresses and remain durable over time.

Insulation Testing: Verifying the thermal and acoustic insulation properties of the walls and roof to ensure comfort and energy efficiency in various climates.

Exterior Material Inspection: Checking the quality of the customized exterior finishes to ensure they meet durability and aesthetic standards.

Utility Checks: Ensuring all pre-installed utilities, including plumbing and electrical systems, are functional and comply with relevant safety regulations.

Packaging and Transportation

Once production is complete and all quality checks have been passed, the flat pack container house is prepared for shipment. The modular design allows the house to be disassembled into flat-packed sections, which are securely packaged for transport. This efficient packing method reduces shipping costs and allows multiple units to be transported in standard shipping containers or on flatbed trucks. The customized exterior materials, such as stone veneer or wood paneling, are carefully protected to prevent damage during transit. Upon arrival, the flat pack container house can be easily assembled on-site with minimal tools and labor.

After-Sales Service

The purchase of a custom exterior flat pack container house includes comprehensive after-sales support, such as:Warranty: A standard one-year warranty covers structural components, materials, and finishes.Customer Support: A dedicated team is available to assist with assembly, provide technical support, and answer any questions related to customization or maintenance.Replacement Parts: In case of damage to exterior finishes or other components, replacement parts can be quickly shipped to ensure minimal disruption to use.

Payment Settlement

Flexible payment options are available for clients purchasing a custom exterior flat pack container house. Typically, a 30% deposit is required to initiate production, with the remaining balance due upon delivery or completion of the project. Clients can choose from several secure payment methods, including bank transfers, letters of credit, or other mutually agreed-upon methods.

Conclusion

The custom exterior flat pack container house offers the perfect blend of modern modular construction and personalized design. With a variety of exterior finishes to choose from, this home can be tailored to match any aesthetic preference, whether it be contemporary, rustic, or industrial. Its efficient construction, customizable design, and cost-effectiveness make it an excellent option for residential, commercial, or vacation properties, offering a unique, sustainable, and stylish living solution.