40ft Customized Modular Container House : Luxury Living Container House

Product Specifications

Removable container houses usually come with a standard dimension of 6 meters in length, 3 meters in width, and 2.5 meters in height, weighing approximately 1.5 tons. Stability is ensured by a steel - frame structure, and they are fitted with insulated wall panels that preserve a pleasant indoor temperature. Engineered for durability, these units possess an exterior protective coating that combats corrosion and harsh weather, rendering them adaptable to varied environments. The interior can be customized to fulfill different demands, whether it’s a living zone, a workspace, or a storage facility.

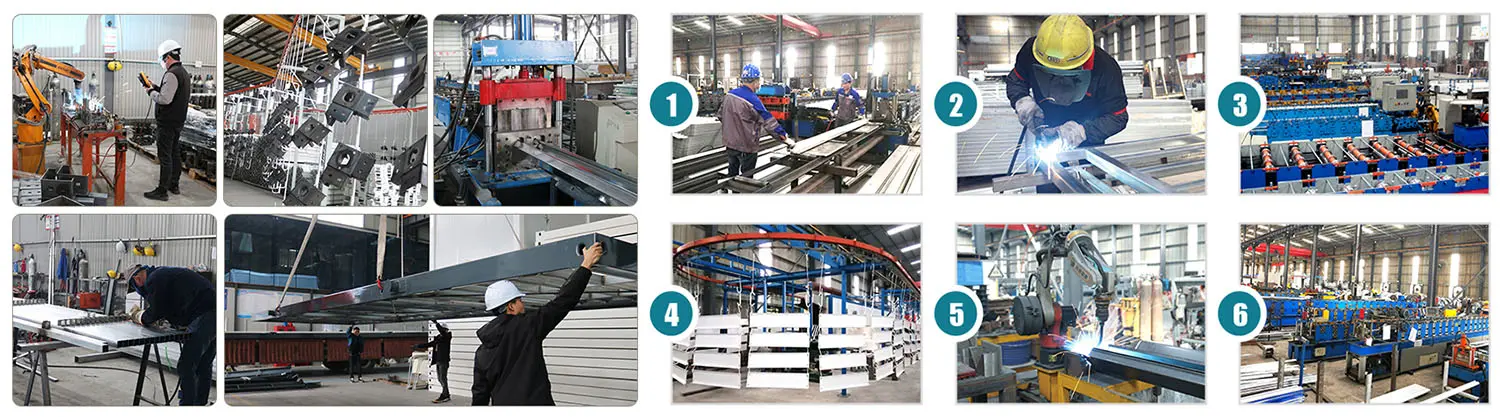

Raw Materials

Detachable container house construction depends on top - grade raw materials to guarantee durability and comfort. The main material is hot - dip galvanized steel, recognized for its anti - rust characteristics and structural soundness. The walls are equipped with high - density polyurethane foam for thermal insulation, assisting in maintaining an ideal temperature within the unit. Eco - friendly PVC is applied to the flooring, which offers a surface that is not just waterproof and slip - resistant but also simple to clean and maintain. These materials make sure that the houses are sturdy, comfortable, and appropriate for different conditions.

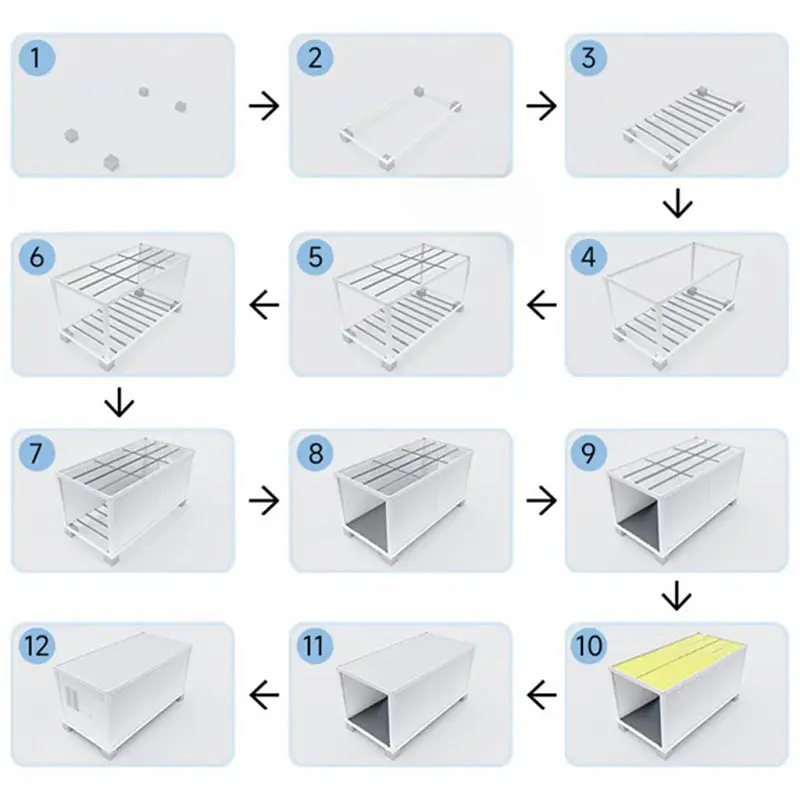

Production Process

The production of detachable container houses is carried out with precision and efficiency. It starts with cutting steel beams to the required dimensions, followed by welding to create the frame structure. The steel is then coated with a corrosion-resistant layer to extend its service life. Wall panels with insulation are attached to the frame, and exterior and interior finishes are applied. The unit is assembled using advanced machinery, which ensures each part fits perfectly. Finally, windows, doors, and electrical components are installed, with the entire unit undergoing a detailed quality check before being packaged for shipping.

Usage Scenarios

Detachable container houses offer a flexible solution for a variety of needs. They are widely used on construction sites as temporary offices or living quarters for workers. In remote or scenic locations, these units serve as cost-effective holiday cabins or guest accommodations. Their quick assembly makes them ideal for emergency housing in disaster relief efforts, providing safe shelter in critical times. Additionally, they are well-suited for use as mobile clinics, pop-up shops, or field research stations, adapting easily to changing requirements.

Quality Assurance

Ensuring top-tier quality is central to the production of detachable container homes. Every unit undergoes rigorous testing to guarantee structural safety and long-term durability. Weld joints are rigorously checked for structural robustness to confirm the frame’s integrity, while insulation performance is evaluated to ensure it maintains a stable indoor environment. Water-tightness tests are conducted to verify the units’ sealing integrity, ensuring they can endure heavy rainfall. Additionally, products are tested for wind resistance and seismic stability, guaranteeing steadfastness in extreme weather conditions. The entire manufacturing process adheres strictly to ISO9001 quality management standards, ensuring consistent excellence across all units.

Packaging and Transport

Once production and inspection are complete, detachable container houses are carefully packaged to prevent damage during transportation. Each component is wrapped in protective materials such as foam boards and bubble wrap. Thanks to their modular design, the units can be disassembled and packed into flatbed trucks or standard shipping containers, simplifying the transport process. Shock-absorbing measures are implemented during loading and unloading to minimize the risk of damage, ensuring that the units arrive at the customer's location ready for easy assembly.

After-Sales Support

The company provides extensive after-sales support to ensure that customers are fully satisfied with their purchase. A one-year warranty covers structural defects and component replacements, while a dedicated support team is available 24/7 to assist with technical questions or installation guidance. For larger projects, professional technicians can be sent to the site to oversee the assembly process, ensuring everything is set up correctly. This proactive support ensures that customers can rely on the product’s performance long after the purchase.

Payment and Settlement Options

To facilitate a smooth transaction, the company offers several payment methods, including bank transfer, wire transfer, and letters of credit. Generally, a 30% deposit is required to begin production, with the balance due upon the completion and acceptance of the product. For bulk orders or long-term clients, flexible payment terms can be arranged, allowing for more convenient financing. This approach ensures a seamless experience for customers, from order placement to the delivery of their units.

Detachable container houses provide a modern, adaptable solution for diverse living and working spaces. From their careful production process to comprehensive after-sales support, each aspect of these units is designed to meet the evolving needs of customers while maintaining high standards of quality and service.